Brake Repair in West Bend WI

When you need an auto repair center that you can trust with an important job, like brake repair, look no further than Auto Safety Center in West Bend, WI. As a community fixture, our customers (and their safety) mean everything to us. Our auto mechanics make it their mission to do their best every day, to help keep you as safe as possible on the roads. Our auto repair center can help with inspection, service, or replacement on any brake repair issues you might have.

Your brakes are essential in keeping you safe on the roads, especially in West Bend, WI. The icy & snowy conditions of our West Bend winters wreak havoc on brake systems. Combine that with the muddy and wet conditions of summer, and it makes it even more essential to find an auto repair center qualified to handle your brake repair. Auto Safety Center can assist you with your entire brake system and brake repair requirements, including your brakes, calipers, brake pads, master cylinder, and so much more. Our auto mechanics are fully prepared to handle anything from diagnosis to replacement and brake repair.

What We Offer:

- Road testing, before and after

- Free brake system inspection

- Detailed service reports

- Certified work performed by auto mechanics that care

- Industry-leading equipment

- Industry-leading parts, like BG Products

- Top -of-the-line 50,000-mile Warranty

- We guarantee your satisfaction

Auto Safety Center has humble roots grounded in community-driven quality work and dedication to people-first. We simply want to be the best auto repair shop that we can be in West Bend, WI. That is why we offer free loaner cars to customers, to help[ reduce the burden that auto repair places on you. Auto Safety Center provides a top-of-the-line warranty providing 50,000-mile coverage. We use DVI to give our customers more information about their vehicles, and we keep you updated on everything happening as we move forward. Check out what some of our previous customers had to say about our shop:

“I appreciate all the hard work and staying late that Tim did to finish up my car in one day. I would not take any of my vehicles anywhere else. Merry Christmas and a Happy New Year to the whole team!” -- Jim B.

When you need a brake repair service that you can rely on, contact Auto Safety Center in West Bend, WI. Auto Safety Center is a YES company – schedule an appointment today for quick approval, auto repair, and assistance. We’re also on Facebook! We’re located at 3700 W. Washington Street, West Bend, WI 53095, on the corner of Shepherd’s Drive and Washington Street, right across from the Fleet Farm. Our shop hours are Monday - Friday, 7:30 AM - 5:30 PM. We Fix Just About Everything!

Disc brake repair in West Bend WI. Auto Safety Center performs all make, cars, vans, trucks, SUV, 4x4, domestic and import brake repair in the West Bend Wisconsin

Harsh winter conditions and road salt causes rust and corrosion of brake parts leading to rapid rear brake wear and total brake failure in extreme cases. Routine brake inspections ensure a safe vehicle. Regular brake inspections and lubrication can prevent expensive parking brake repair and warn of needed rusted brake line repair. Auto Safety Center performs all auto brake repairs in West Bend WI including ABS brake repairs, anti lock brake repairs, auto brake job, brake pad repair, brake line repair, and general auto brake service.

Auto Safety Center performs all brake repairs including brake master cylinder repair in West Bend WI.

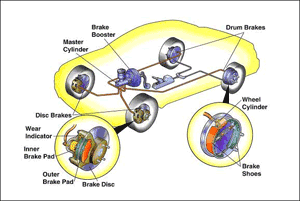

Brake system component diagram shows complete brake system with disc brake pads, brake calipers, brake rotor discs, brake master cylinders, power brake booster, brake hoses, brake lines, drum brake shoes, wheel cylinders, and parking brake system.

Auto Safety Center performs all West Bend WI brake repair including brake hose replacement in West Bend WI.

Auto Safety Center performs all brake repairs including brake shoe replacement in West Bend WI.

Auto Safety Center performs all brake repairs including brake pad replacement in West Bend WI.

Auto Safety Center performs all brake repairs including power brake booster repair in West Bend WI.

Auto Safety Center performs all brake repairs including brake rotor replacement in West Bend WI.

Auto Safety Center performs all brake repairs including brake drum repair in West Bend WI.

Auto Safety Center performs all brake repairs including anti lock brake repair in West Bend WI.

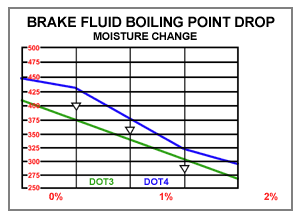

New brake fluid is clean and clear. Dirty, neglected brake fluid looks like used engine oil and can compromise the performance of your brake system and cause severe, costly damage. If you haven't serviced your brake system lately, now's the time. Auto Safety Center performs brake repairs, brake hose replacement, brake master cylinder replacement, brake fluid flush in West bend WI.

Brake fluid boiling point chart shows why you should do routine brake fluid flush